In the world of metal finishing, precision, quality, and efficiency are critical factors that can make or break the success of a plating operation. Over the years, technological advancements in rectifier systems have played a key role in improving these elements. One of the most significant innovations in recent years is the pulse rectifier. By offering greater control over plating conditions and optimizing energy delivery, pulse rectifiers are revolutionizing metal finishing processes across various industries.

What Is a Pulse Rectifier?

A pulse rectifier is a type of power supply used in electroplating systems that delivers electrical current in pulses rather than a continuous flow. These pulses can be programmed in terms of on-time (Ton) and off-time (Toff), providing the ability to control the duration, frequency, and intensity of the current applied during the plating process.

Unlike traditional DC (Direct Current) rectifiers, which supply a constant stream of current, pulse rectifiers alternate between on and off states at specific intervals, allowing for greater flexibility and fine-tuning of plating conditions.

Pulse rectifiers contribute to greater energy efficiency in plating systems. By controlling the duration and frequency of current pulses, the plating process becomes more efficient, requiring less energy to achieve the same results as traditional continuous rectifiers. This efficiency not only helps reduce operational costs but also minimizes electrolyte degradation, extending the lifespan of the electrolyte solution and reducing waste.

The impact of pulse rectification goes beyond just the aesthetics and uniformity of the plated surface. By modulating the current, pulse rectifiers can help optimize the material properties of the plated metal. This is especially beneficial in applications where specific characteristics, such as hardness, wear resistance, or corrosion resistance, are critical.

As industries continue to demand higher-quality coatings with greater precision, pulse rectifiers are proving to be a key technology in achieving these goals. By offering precise control, reducing heat generation, and improving material properties, pulse rectifiers are helping to revolutionize metal finishing processes.

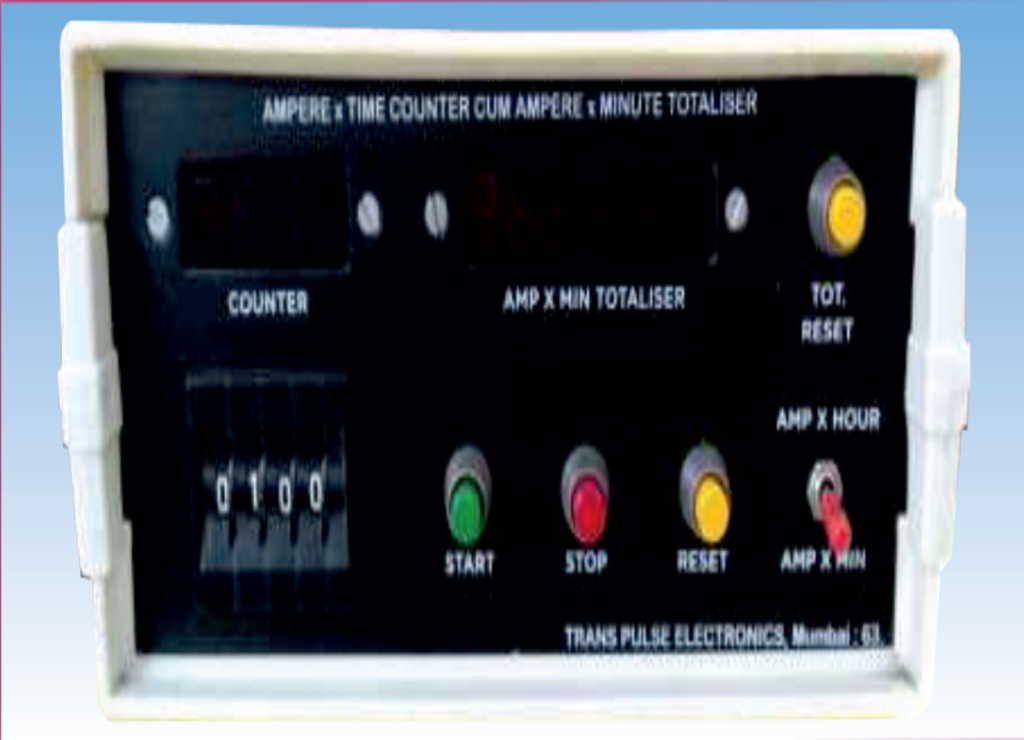

At Trans Pulse Electronics, we are proud to offer state-of-the-art pulse rectifiers that provide advanced control, reliability, and efficiency for all types of electroplating applications.

Why Pulse Rectifiers Are a Game-Changer in Metal Finishing

1. Enhanced Control Over Plating Conditions

One of the key advantages of pulse rectifiers is their ability to provide precise control over plating parameters. By adjusting the pulse width (the duration of the "on" and "off" cycles), operators can manipulate the deposition process to achieve specific coating characteristics. This fine-tuned control can influence:

- Deposit uniformity: Pulse rectifiers help produce more uniform coatings, reducing the risk of defects such as pitting, uneven thickness, and roughness.

- Coating adhesion: Pulsed currents can improve the adhesion of the plated metal to the substrate, which is especially important in industries like aerospace and automotive, where reliability and durability are paramount.

- Surface finish quality: By adjusting the pulse rate and current, the surface finish can be enhanced, making it smoother and more aesthetically pleasing, especially in processes like chrome plating or gold plating.

2. Reduced Heat Generation

In traditional continuous DC rectifiers, the current flows continuously, generating heat during the electroplating process. This heat can negatively affect the quality of the coating and, in some cases, lead to undesirable deformation of the substrate or the coating.

Pulse rectifiers, however, operate in a pulsed mode, significantly reducing heat buildup. The "off-time" in the pulse cycle allows for cooling, preventing the substrate from overheating and ensuring the plating process remains efficient. This reduction in heat generation makes pulse rectifiers ideal for delicate substrates and precious metals that require more controlled temperature conditions.

Whether you're looking to enhance the quality of your chrome plating, improve the consistency of your gold plating, or optimize your anodizing processes, pulse rectifiers can help you achieve the best possible results.

Key Applications of Pulse Rectifiers in Metal Finishing

Pulse rectifiers are being used in a variety of metal finishing applications, from jewelry plating to automotive coatings. Here are a few key areas where pulse rectifiers are making a significant impact:

1. Gold and Silver Plating

For high-precision applications such as gold plating and silver plating, pulse rectifiers provide the control needed to achieve consistent thickness and high-quality finishes. The ability to adjust the pulse frequency allows operators to achieve the desired color and texture for jewelry, electronic connectors, and decorative coatings.

2. Chrome and Nickel Plating

In chrome plating, pulse rectifiers are used to reduce defects such as burns or orange peel on the surface, which are often caused by excessive heat during plating. Pulse rectifiers enable a smoother finish and better wear resistance, making them ideal for automotive parts, industrial tools, and decorative finishes.

In nickel plating, the use of pulse rectifiers improves the coating's hardness, which is important for applications in the aerospace, automotive, and machinery sectors.

3. Electrophoretic Deposition (EPD)

Pulse rectifiers are also increasingly used in electrophoretic deposition (EPD), a process used to apply coatings to various substrates, including metals, plastics, and ceramics. The pulsed current enables better control over the deposition rate, improving the quality of the coating and ensuring uniform thickness even on irregularly shaped objects.