In the world of electroplating, precision is everything—especially when it comes to pen plating. Unlike traditional plating methods, pen plating is a highly specialized process that allows for selective plating on small or intricate areas. Whether you're plating a tiny connector on an electronic component or adding a fine finish to a delicate jewelry piece, pen plating offers an unparalleled level of control and accuracy.

At Trans Pulse Electronics, we understand the challenges that come with precision plating, which is why we've developed custom-built Pen Plating Units designed to meet the specific needs of our customers. In this ultimate guide, we'll explore what pen plating is, how it works, and why our Pen Plating Units are the go-to solution for achieving flawless finishes in small-scale electroplating applications.

What Is Pen Plating?

Pen plating is a precision electroplating technique used to deposit metal coatings on small or localized areas of a substrate. Unlike traditional electroplating methods, which involve immersing the entire item in a plating bath, pen plating uses a handheld electrode or "pen" to selectively plate specific areas. This process allows for highly localized plating of small parts, intricate designs, or even repair jobs on larger components.

Pen plating is ideal for applications that require detailed work, such as jewelry plating, electronics, aerospace components, and medical devices. The process is precise enough to handle fine details and can be used for spot plating, repairing worn-out coatings, or applying thin layers of precious metals like gold, silver, or platinum.

How Does Pen Plating Work?

Pen plating involves using a specially designed electrode in the form of a pen-like tool that is connected to a power source. Here's how the process works:

Prepare the Surface: Just like any other electroplating process, pen plating requires proper surface preparation. This involves cleaning the item thoroughly to remove any dirt, oils, or oxidation, ensuring optimal adhesion of the plating material.

Attach the Pen Electrode: The pen electrode, which is typically equipped with a small anode, is connected to a DC power supply. The electrode is then applied to the targeted area of the component, where it will deposit the desired metal coating.

Apply the Current: When the pen electrode touches the part, electrical current flows through the substrate, and metal ions from the electrolyte are reduced onto the surface, forming a thin, even coating. The current is controlled, allowing for precise plating of small areas.

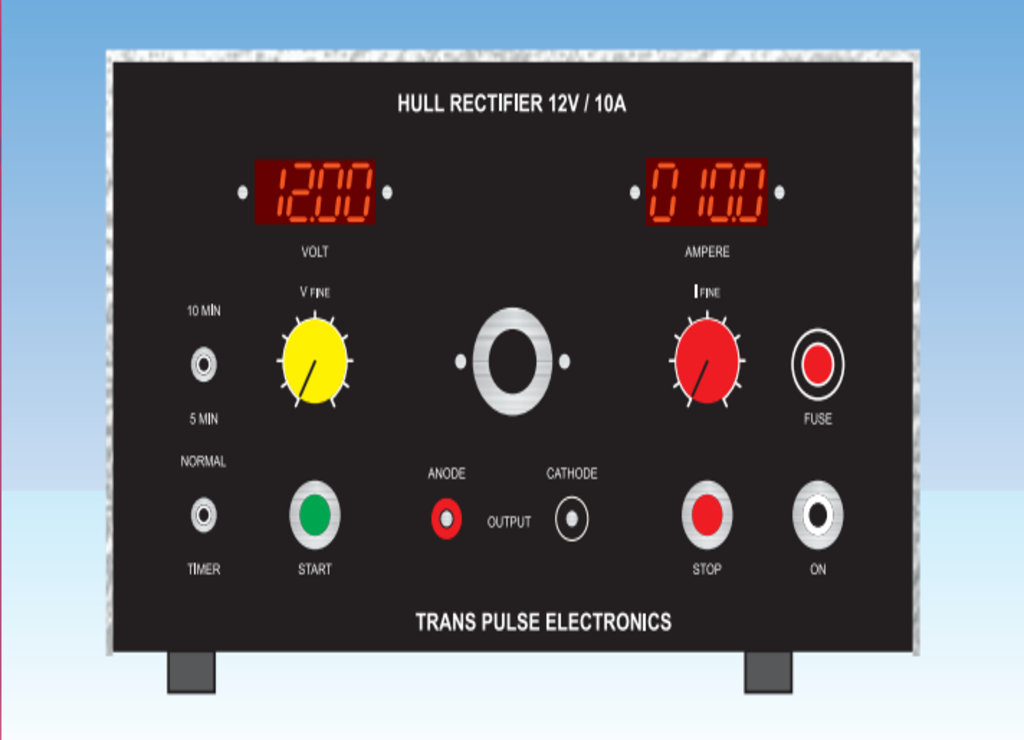

Monitor the Plating Process: The plating process can be monitored using a digital display on the pen plating unit, showing real-time information about the voltage, current, and other parameters. Some units also feature a timer for precise control over plating time.

Finish and Clean: Once the plating is complete, the part is rinsed and dried, ensuring a clean, uniform finish.

Why Choose Our Pen Plating Units?

1. Precision Control

Our Pen Plating Units feature microcontroller-based control systems, allowing you to precisely adjust the current and plating time. Whether you need a thin layer of plating or a thicker coating, our units give you the flexibility to achieve exactly what you need.

- Programmable Settings: You can set specific parameters for different jobs, ensuring consistency across batches.

- Digital Meters: Our units come equipped with digital meters for accurate monitoring of peak current and voltage, providing you with real-time feedback on the plating process.

2. Ease of Use

Our units are designed with simplicity in mind. They feature intuitive interfaces that make them easy to use, even for operators with limited electroplating experience.

- Compact and Portable: Our pen plating units are portable, making them ideal for both small workshops and large industrial settings.

- Versatile Applications: You can easily switch between different metals and coatings, including gold, silver, nickel, and chrome.

3. Low Ripple and High Efficiency

Our Pen Plating Units are engineered to provide low ripple, ensuring a stable current supply throughout the plating process. This leads to smoother, more uniform coatings and minimizes defects like roughness or unevenness.

- Short-Circuit Protection: All units are designed to be short-circuit proof, ensuring the safety of both the equipment and the operator.

- Auto-Cutoff Feature: Our Pen Plating Units include an auto cutoff function and a buzzer alarm, providing an added layer of safety.

Applications of Pen Plating

Pen plating is perfect for a wide range of applications, including:

- Jewelry Plating: Adding a high-quality gold or silver finish to intricate designs.

- Precision Electronics: Plating small connectors and components used in circuit boards or microelectronics.

- Restoration and Repair: Repairing worn or damaged plating on delicate components.

- Aerospace and Automotive Parts: Coating small parts that need to withstand high temperatures and wear.

Whether you're a small business owner, a jewelry maker, or an engineer, our Pen Plating Units offer the precision and flexibility needed to achieve the perfect coating every time. With easy-to-use features, precise control, and customizable settings, our units are designed to meet the demands of your most intricate plating projects.

Ready to enhance your plating process? Contact us today to learn more about our Pen Plating Units and find the perfect solution for your precision plating needs.