In the world of electroplating, precision and efficiency go hand in hand. Whether you're plating intricate jewelry, small electronics, or large industrial components, achieving consistent, high-quality results requires a combination of the right equipment, optimal settings, and precise timing. One often overlooked yet crucial component in any electroplating setup is the digital timer.

At Trans Pulse Electronics, we understand that managing plating time is just as important as controlling voltage and current. Our digital timers play a pivotal role in streamlining plating operations, improving process control, and maximizing overall efficiency. In this blog, we’ll explore how digital timers contribute to the effectiveness of electroplating systems and why they’re an essential tool for any plating operation.

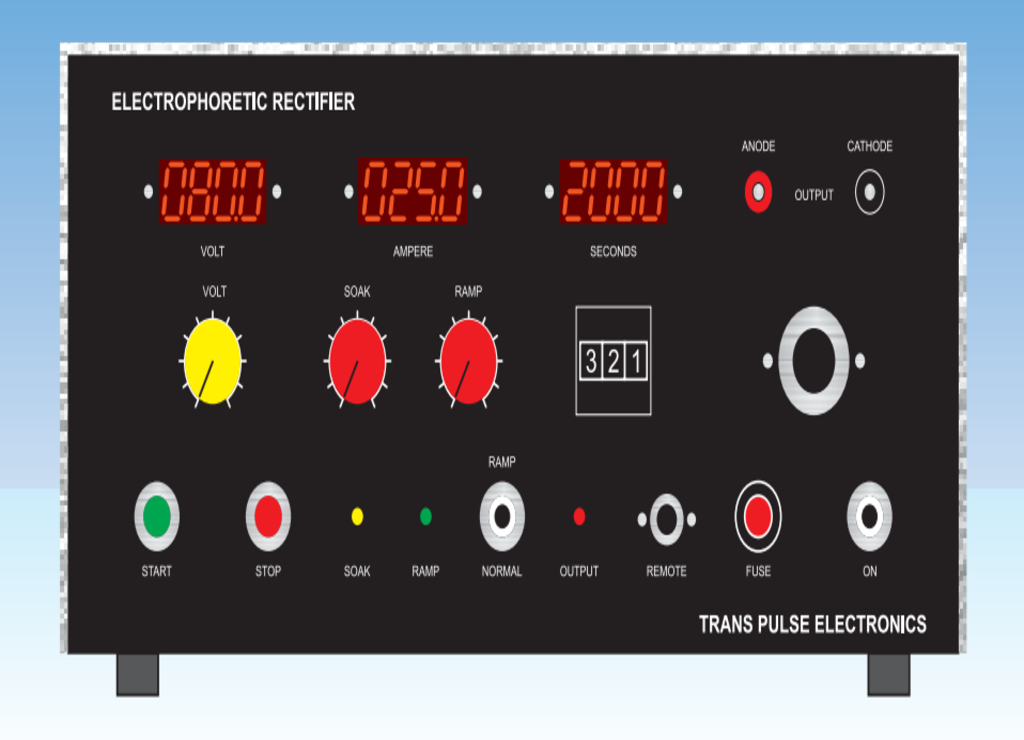

ACCESSORIES

The Importance of Timing in Electroplating

Electroplating is a complex process that involves the deposition of a metal onto a surface using an electric current. While factors like current density, voltage, and plating solution composition are crucial to achieving a high-quality finish, time is equally important. If the plating time is too short, the coating may be too thin and prone to damage. On the other hand, if the plating time is too long, the coating may become too thick or uneven, leading to imperfections.

Digital timers are used to monitor and control the exact plating duration, ensuring that each component receives the appropriate amount of plating material, while also optimizing the use of resources.

2. Automation and Increased Throughput

Digital timers help automate the electroplating process, especially when they are integrated with other equipment such as rectifiers and controllers. This automation significantly increases throughput, allowing operators to plate more items in less time, without sacrificing quality.

- Set and Forget: With programmable digital timers, operators can set the exact duration for each step of the plating process (e.g., soak time, ramp time, or plating time), and the system will automatically stop when the preset time is reached.

- Reduced Downtime: Automated timing helps prevent unnecessary delays between plating cycles. Once the timer completes its countdown, the system can trigger a stop signal, move the item to the next phase, or alert the operator that it's time for the next batch.

4. Reducing Material Waste and Energy Consumption

Efficiency isn't just about time management—it's also about resource optimization. By controlling plating time with a digital timer, operators can minimize waste of precious plating materials like gold, silver, or other metals. Over-plating can lead to unnecessary material usage, while under-plating can result in poor-quality coatings.

- Optimized Plating Time: Digital timers help prevent over-plating by stopping the plating process once the set time has elapsed. This ensures that each component receives the correct amount of metal, reducing waste and saving on raw materials.

- Energy Savings: By automating the plating process and ensuring that only the necessary amount of time is spent plating, digital timers also help optimize energy usage, leading to more efficient operations.

How Digital Timers Improve Efficiency in Electroplating

1. Precision Control Over Plating Time

One of the most significant advantages of using digital timers in electroplating systems is their ability to offer precise control over plating time. With traditional mechanical timers, operators often had to manually adjust or track the time, which can lead to errors or inconsistencies. Digital timers, on the other hand, provide an accurate, repeatable countdown, ensuring that each plating cycle is perfectly timed.

- Consistent Results: With accurate time control, every batch of electroplated items is subjected to the same process conditions, guaranteeing uniformity and consistency in the plating thickness.

- Elimination of Human Error: Digital timers minimize the risk of human error by providing automated timing cycles. This allows operators to focus on other aspects of the process, such as monitoring the quality of the plating or making adjustments to the current.

3. Increased Process Repeatability

Consistency is key to quality electroplating. When digital timers are used in combination with programmable rectifiers and other advanced control systems, they help achieve repeatable plating cycles across multiple batches. Whether you're running a high-volume production line or working on prototypes, digital timers ensure that the plating process is the same every time.

- Batch Control: For industries that require plating in batches, such as electronics or jewelry manufacturing, digital timers help ensure that all items in a batch receive the same plating time, resulting in uniform coating thickness.

- Customizable Settings: Digital timers allow for easy adjustment of the plating duration based on the specific needs of each batch. This flexibility is crucial when dealing with different substrates or varying metal deposition requirements.

Flexibility for Multi-Stage Processes

In complex electroplating jobs, the process often involves multiple stages, each with its own time requirements. For example, the pre-plating stage may require a certain amount of soak time, while the main plating stage requires different time settings. Digital timers allow you to manage these multi-stage processes with ease, ensuring that each step of the electroplating process is completed within the right time frame.

- Multiple Time Settings: Advanced digital timers can be programmed for different stages of the electroplating process, allowing for precise time control at each phase of the operation.

- Time Staggering: For processes that involve varying conditions such as current ramps or temperature changes, digital timers can be synchronized with other equipment to achieve precise control over plating cycles.

Benefits of Digital Timers in Electroplating

- Enhanced Precision: Digital timers deliver precise, reliable control over plating duration, which is critical for achieving uniform plating thickness and high-quality finishes.

- Improved Efficiency: Automation reduces the need for constant monitoring, allowing operators to focus on other tasks and increasing overall throughput.

- Consistency and Repeatability: Digital timers ensure that each plating cycle is the same, leading to consistent results across multiple batches.

- Cost Savings: By optimizing plating time and minimizing waste, digital timers help reduce the consumption of expensive plating materials and energy.

- Flexibility: Customizable time settings allow operators to adjust plating durations for different applications, ensuring that the system can handle a variety of plating jobs.

Digital Timers in Trans Pulse Electronics Electroplating Systems

At Trans Pulse Electronics, we integrate advanced digital timers into our electroplating systems to help you maximize productivity and ensure precise control over your plating process. Our systems are designed to provide the flexibility, accuracy, and automation that your operations require, whether you're plating small, delicate components or handling large production runs.

Our digital timers are:

- Easy to program and adjust to suit a wide range of electroplating needs.

- Integrated with rectifiers and other systems to enhance overall process control.

- Equipped with memory backup, ensuring your settings are retained even during power outages.